Scan Head with Laser Beam Shapers Nearly Doubles Welding Production; Speeds Up 3D Printing

SCANLAB GmbH, together with its sister companies Blackbird Robotersysteme GmbH and Holo/Or Ltd. is developing a promising new system for laser applications such as laser welding of bipolar plates and additive manufacturing (metal 3D printing).

Fuel cell technology was considered a niche market for a long time. But due to the transition phase in energy generation and the search for alternative drives, the market demand may grow substantially. For efficient mass production, an increase of throughput in welding of metal bipolar plates, used to build the stacks in a fuel cell, is needed.

High welding speeds require fast scan systems and high-power lasers, which are both available. However, it's the welding process itself that determines the maximum reachable speed. Weld seam failures such as humping effects and undercut occur when a certain speed limit is exceeded.

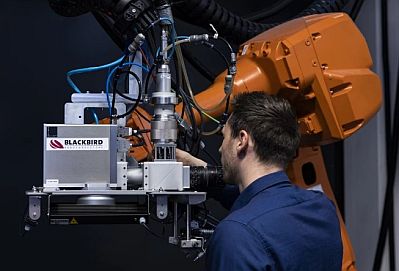

Blackbird Robotersysteme set up a test rig integrating the 2D scan head intelliSCAN from SCANLAB and HOLO/OR's latest development -- the Flexishaper, a full range adjustable beam shaper. The necessary beam shape was determined based on welding process simulations. The layout of the utilized beam shaper is the result of a combined optical design, integrating both diffractive optical elements (DOE) and scan system. The processing tests demonstrated to shift the speed limit of failure free welding speed from 45 m/min up to 70 m/min.

Process Could Benefit Metal 3D Printing

Thin sheet welding of bipolar plates has similar requirements to laser powder bed fusion (LPBF) processes. Both require scan field sizes up to 500 x 500 mm² with a typical processing speed around 1m/s and below. Also, in metal 3D printing the processing speed is not limited by the speed of the scanner or the available laser power, but it is mostly the process itself which limits the throughput. Thus, the encouraging laser welding results are the first step on the way to further optimize LPBF processes as well.

The next steps will be to test the laser welding concept in a larger scale setup and to pursue different applications in parallel. As the fiberSYS meets requirements of both LPBF and laser welding processes, the integration of DOEs into this scan system, particularly suited for multi head laser machines, was included in the development road map.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::